NEWS & EVENTS

Oct 26 - Oct 29, 2025

Join us at 2025 ISPE Annual Meeting, with KeyPlants!

|

Sapphire Ballroom - 204 (KeyPlants)

Charlotte Convention Center, Charlotte, NC We will be exhibiting at the 2025 ISPE Annual Meeting & Expo in Charlotte, NC with our modular construction partner KeyPlants Please stop by our booth to discuss the advantages of utilizing our modular construction approach for your next pharma, biotech, etc. manufacturing facility, expansion, or conversion. We look forward to seeing you there! |

Oct 28 - Oct 30, 2025

Join us at EATS, with Lodige Process Technology!

|

Booth #4315 (Lodige Process Technology)

McCormick Place Convention Center - Chicago, IL We will be exhibiting with Lodige Process Technology at the equipment automation technology show (eats) Oct 28- Oct 30 at the McCormick Place Convention Center in Chicago, IL. Please come see us at Booth 4315 to learn more about Lodige's mixing and powder processing systems for food, pharmaceutical, cosmetics, and other industries. We look forward to seeing you there! |

April 29 - May 1, 2025

Join us at IPBS, with Hecht!

|

Booth #1335 (Hecht)

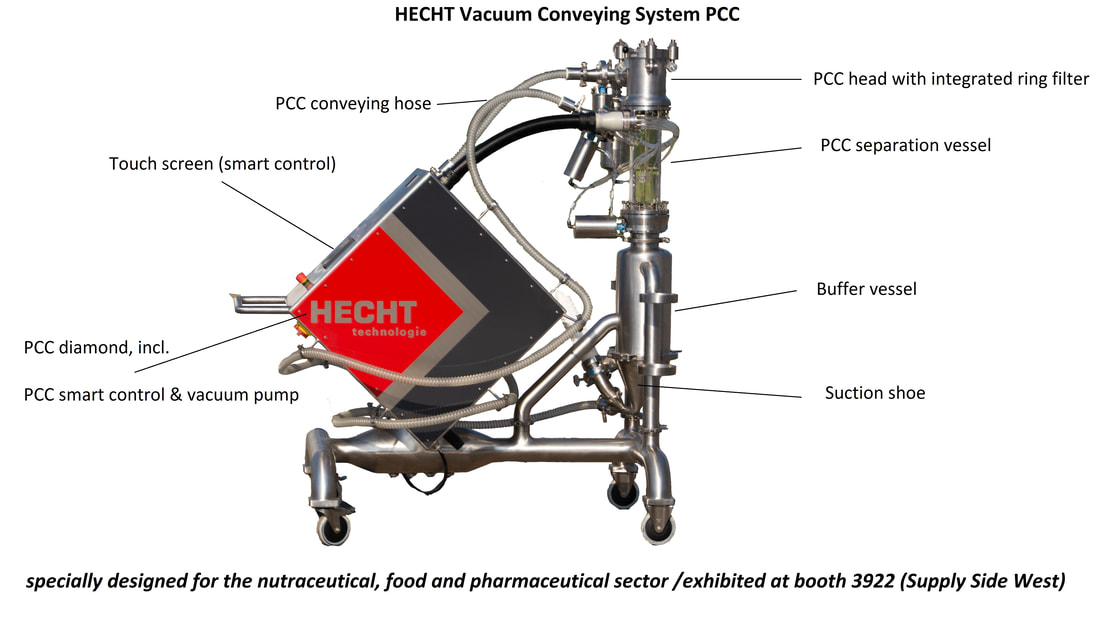

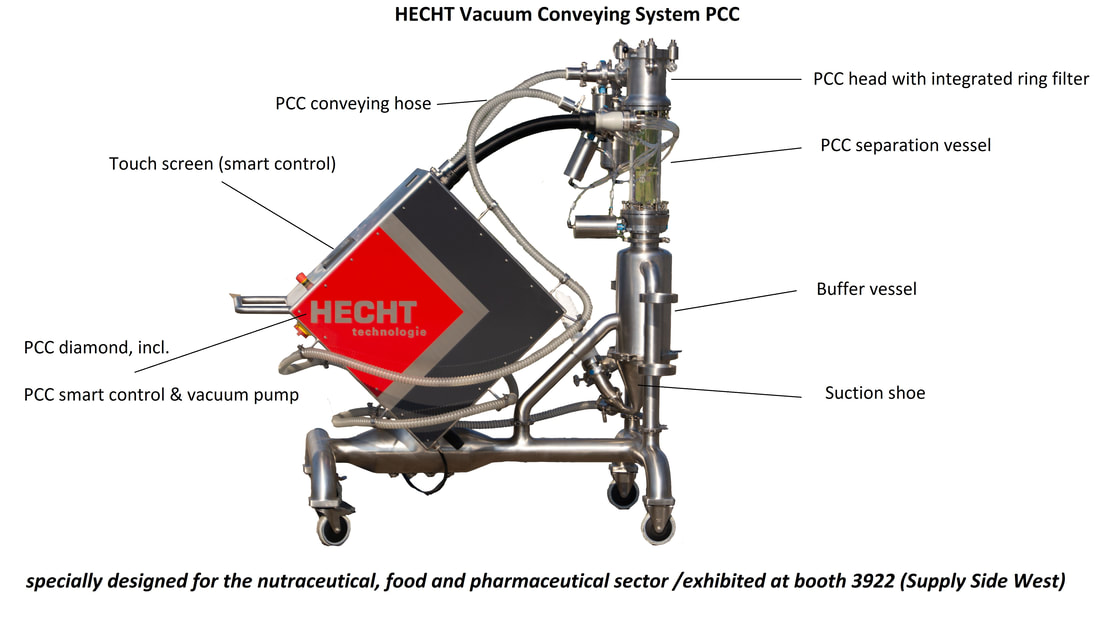

Donald E. Stephens Convention Center - Rosemont, IL We will be exhibiting with Hecht at IPBS April 29- May 1 at the Donald E. Stephens convention center in Rosemont, IL. Please come see us at Booth 1335 to learn more about Hecht's bulk powder handling systems for food, pharmaceutical, cosmetics, and more. We will be showcasing our PCC vacuum conveyor, endless liner filling head, and more. We look forward to seeing you there! |

April 1-3 2025

Join us at Interphex, with KeyPlants

|

Booth 2701 (KeyPlants))

Javits Center - New York City, NY We will be exhibiting with KeyPlants at Interphex April 1-3 at the Javits Center in New York City. Please come see us at Booth 2701 and learn more about modular and hybrid construction for GNC manufacturing facilities and suites. We look forward to seeing you there! |

Nov 11 2024

SortStar Bottle Unscrambler from Capmatic

|

Capmatic’s SortStar automatic bottle unscrambler is a great add-on to any packaging line running plastic bottles. Its unique design features centrifugal discs and adjustable guides and it is capable of unscrambling almost all plastic bottles. In addition to being compatible with most bottles, it does not require change parts for different bottles and changeovers are fast and repeatable. Most plastic bottles can be unscrambled with this system including round, square, rectangular, and oval bottles at speeds up to 300 BPM.

Please CONTACT US or reach out to us on LinkedIn to learn more about the SortStar bottle unscrambler or any of Capmatic’s other solutions for primary packaging. We would love to discuss your packaging needs and help determine whether our solutions are a good fit for your business. |

|

Oct 17 2024

Hecht PCC Vacuum Conveyor

|

One of Hecht's bestselling systems is the PCC vacuum conveyor. This versatile solution has numerous applications where powder needs to be safely conveyed such as from discharging stations, to filling stations/packaging lines, and to and from different processes. The benefits of this system are:

If you have a conveying application you want us to look at, please CONTACT US or reach out to us on LinkedIn. We would love to discuss Hecht's vacuum conveyors and other material handling systems in detail with you and your team. |

|

Oct 11 2024

CT HC-3200 Automatic Cartoner with Leaflet, Bottle, and Syringe Placement for Pharma Application

|

Consolidated Technologies has a variety of standard solutions for common end-of-line packaging applications. When these solutions don't fully meet customers' packaging requirements, they can be customized to meet their specific needs. The system shown in the video is built to pack a leaflet, a bottle, and a syringe in a single carton.

The system shown in the video is equipped with:

If you have a unique end of line packaging application that you would like us to look at, please email us at info@modwave.com or reach out to us on LinkedIn to learn more about CT’s cartoning systems or other end of line packaging systems. We would love to talk to you about your packaging needs! |

|

Oct 01 2024

CT Unicell-20R All-in-one Case Erector and Robotic Case Packer

|

Are you looking for a cost efficient solution for case packing? Consolidated Technologies (CT) offers several different solutions that can be customized to fit your unique needs. Please take a look at the short video for an example of a case packing solution (Unicell-20R) designed and built by CT capable of case erection, packing bags of frozen berries into erected cases, and sealing top and bottom of cases with glue.

The benefits of Consolidated Technologies’ Unicell-20R are:

Please email us at info@modwave.com or reach out to us on LinkedIn to learn more about CT’s case packers or other end of line packaging systems. We would love to talk to you about your packaging needs! |

|

Sep 20 2024

Axy Peristaltic Dosing Station w/ filling, capping, and labeling

|

Capmatic builds systems for many applications including diagnostics. If you are looking to fill micro tubes, Capmatic’s Axy Monoblock system can provide precise filling via peristaltic pump for a wide variety of micro tubes and fill levels. Additionally, the Axy system is capable of capping, labeling, and rejection of defective finished micro tubes.

Capmatic’s Axy Micro Tube Dosing Station offers:

Please email us at info@modwave.com or reach out to us on LinkedIn to learn more about Capmatic’s primary packaging solutions for diagnostic, biotech, and other life science industries. We welcome the opportunity to learn more about your packaging needs. |

|

Sep 12 2024

All-in-one Case Packing and Palletizing Systems from Consolidated Technologies

|

ModWave partners with Consolidated Technologies to offer end of line packaging solutions to complement our primary packaging solutions from Capmatic. Consolidated Technologies offers solutions for cartoning, case packaging, and palletizing made out of stainless steel and anodized aluminum. In addition to standalone solutions, they also offer all in one and customized fully automated solutions catered to your products, including systems for all in one case packaging and palletizing.

The advantages of Consolidated Technologies all-in-one systems are:

Please email us at info@modwave.com or reach out to us on LinkedIn to learn more. We would love to talk to you about your packaging needs. |

|

Sep 6 2024

Monoblock Packaging Systems from Capmatic

|

Packaging is one are of operations where large gains can be made through automation. Packaging commonly consists of a sequence of short duration, precise actions that can be automated mechanically- removing the need for trained operators to perform repetitive, detail oriented tasks such as applying labels to bottles. A MonoBlock system from Capmatic, for example, is capable of automating the following actions in a single system:

|

|

|

June 4-6 2024

Join us at IME South, with Hecht and Lödige Come join us at Booth #520 at the Charlotte Convention Center in Charlotte, NC to discuss Hecht's powder handling systems and Lödige's powder processing solutions!

|

April 16-18 2024

|

|

May 31st, 2022

New POD facility from KeyPlants shortens lead times for pharma production to weeks

by Marija Mladenovic, May 31, 2022

Press Release, Stockholm, Sweden

A new, portable on-demand (POD) facility will help pharma companies dramatically reduce the time it takes to set up new production, speed the development of cutting-edge therapies, and increase production flexibility. The product, called X-press PODs, was developed by KeyPlants, the Stockholm, Sweden-based provider of modular prefabricated facility solutions.

X-press PODs can be on-site and ready for operations anywhere in the world in as few as five weeks for a single POD, compared to a year or more to build a conventional facility from scratch. It also offers maximum flexibility in production. “X-press PODs give manufacturers the flexibility to start small-scale production immediately and then scale out as needed,” says Fredrik Eneqvist, Director Product Development, at KeyPlants. “You just add X-press PODs instead of rebuilding. It’s the fastest way to start or expand production.”

X-press PODs also offer the advantages of a fixed price and time schedule, with a turnkey, integrated approach instead of pieces of a facility/process engineering puzzle. “With X-press PODs, we’re selling a product, not a project,” says KeyPlants’ Head of Sales, David Lindholm. “Pharmaceutical companies can eliminate the time and complexity of specification, bidding, procurement and permitting – to say nothing of supervising construction. This will result in innovative, cost-effective solutions from clinical development to commercialization since total cost of ownership will be reduced.”

With a standardized design, KeyPlants’ X-press solution allows for rapid lead times as short as five weeks when procuring a single X-press POD. X-press also ensures a facility that meets project timelines, without compromising on quality.

“The demand for capacity has increased, and the demand for flexible manufacturing has increased,” Lindholm says. “The demand for local manufacturing has also increased as pandemic-related supply-chain issues have created havoc in many industries around the world. Pharmaceuticals are no exception.”

X-press PODs offer manufacturers the flexibility to choose their own equipment or take advantage of KeyPlants’ capabilities. These capabilities include process design and equipment integration, as well as services to support with automation, design, qualification and process validation.

“X-press PODs are technology agnostic,” Eneqvist adds. “Companies can change functionality by adding or removing walls or ramp up production by connecting additional PODs.”

Versatile, scalable, and always up to dateEneqvist says that X-press PODs can house many different processes across the whole pharmaceutical and biomanufacturing industries. “The speed with which new drugs and therapies are emerging in universities and research facilities all over the world means that a facility designed today might be obsolete a short time after it starts production,” he notes.

The pharmaceutical industry’s trend towards more personalized medicines such as ATMPs (Advanced Therapy Medicinal Products) also impacts the construction of plants.

“Traditional pharmaceutical and biomanufacturing companies typically have a large amount of experience and expertise in high-requirement production, such as aseptic conditions,” he explains. “ATMPs, on the other hand, are often at clinical stage and in the hands of researchers without the same experience in building and running production facilities.”

As these products move from the clinical stage to commercial, the owners face new challenges, but Lindholm says that KeyPlants, as a company that has built pharmaceutical manufacturing plants all over the world, has a thorough understanding of the technical and regulatory requirements, so the facilities will be set up for safe delivery of medicines to patients.

“With X-press PODs, pharma companies can be confident that they will receive a facility that meets their project timelines, without compromising on quality.”

No limitation on scale

As a facility that can be up-sized by adding PODs, X-press PODs has no obvious limitations on its scale-up or scale-out capacity, opening up opportunities for future expansion. At the same time, X-press PODs are also a solution for small-scale production of cell and gene therapies, for example.

“A large, conventional plant would not be cost-effective, given the small number of patients for some of these products,” Lindholm points out. “But X-press PODs make it easy to right-size a facility.”

The portable nature of X-press PODs also means they have the capacity to move from one location to another when required. “This ensures PODs can adapt to evolving needs, which is crucial when keeping up with the fast-moving biomanufacturing landscape,” he adds.

About KeyPlants

KeyPlants, headquartered in Stockholm, Sweden, is a leader in the clean room manufacturing space for the life science industry, having executed 100+ projects globally. Our customers benefit from KeyPlants’ vast experience and expertise, resulting in 30-50% shorter timelines and increased predictability with regards to schedule, cost, and quality. KeyPlants deliver PODs and turnkey facilities including process equipment, utilities, and digital solutions. KeyPlants is part of Masco Group.

www.KeyPlants.com

www.KeyPlants.com/x-presspods/

About Masco Group

Masco Group is an integrated solutions provider, partner to top-tier pharmaceutical and biotechnological companies. Its companies Stilmas, Olsa, BCD, DOC, and KeyPlants, are leaders in clean utilities, process technologies, services and facilities. Headquartered in Milan, Italy, the Masco Group has production sites and subsidiaries in Europe, The U.S., and Asia, serving more than 6,000 clients globally and delivering around 300 projects per year.

For further information, please visit our website or contact:

Marija Mladenovic,

Marketing & Communications

marija.mladenovic@keyplants.com

New POD facility from KeyPlants shortens lead times for pharma production to weeks

by Marija Mladenovic, May 31, 2022

Press Release, Stockholm, Sweden

A new, portable on-demand (POD) facility will help pharma companies dramatically reduce the time it takes to set up new production, speed the development of cutting-edge therapies, and increase production flexibility. The product, called X-press PODs, was developed by KeyPlants, the Stockholm, Sweden-based provider of modular prefabricated facility solutions.

X-press PODs can be on-site and ready for operations anywhere in the world in as few as five weeks for a single POD, compared to a year or more to build a conventional facility from scratch. It also offers maximum flexibility in production. “X-press PODs give manufacturers the flexibility to start small-scale production immediately and then scale out as needed,” says Fredrik Eneqvist, Director Product Development, at KeyPlants. “You just add X-press PODs instead of rebuilding. It’s the fastest way to start or expand production.”

X-press PODs also offer the advantages of a fixed price and time schedule, with a turnkey, integrated approach instead of pieces of a facility/process engineering puzzle. “With X-press PODs, we’re selling a product, not a project,” says KeyPlants’ Head of Sales, David Lindholm. “Pharmaceutical companies can eliminate the time and complexity of specification, bidding, procurement and permitting – to say nothing of supervising construction. This will result in innovative, cost-effective solutions from clinical development to commercialization since total cost of ownership will be reduced.”

With a standardized design, KeyPlants’ X-press solution allows for rapid lead times as short as five weeks when procuring a single X-press POD. X-press also ensures a facility that meets project timelines, without compromising on quality.

“The demand for capacity has increased, and the demand for flexible manufacturing has increased,” Lindholm says. “The demand for local manufacturing has also increased as pandemic-related supply-chain issues have created havoc in many industries around the world. Pharmaceuticals are no exception.”

X-press PODs offer manufacturers the flexibility to choose their own equipment or take advantage of KeyPlants’ capabilities. These capabilities include process design and equipment integration, as well as services to support with automation, design, qualification and process validation.

“X-press PODs are technology agnostic,” Eneqvist adds. “Companies can change functionality by adding or removing walls or ramp up production by connecting additional PODs.”

Versatile, scalable, and always up to dateEneqvist says that X-press PODs can house many different processes across the whole pharmaceutical and biomanufacturing industries. “The speed with which new drugs and therapies are emerging in universities and research facilities all over the world means that a facility designed today might be obsolete a short time after it starts production,” he notes.

The pharmaceutical industry’s trend towards more personalized medicines such as ATMPs (Advanced Therapy Medicinal Products) also impacts the construction of plants.

“Traditional pharmaceutical and biomanufacturing companies typically have a large amount of experience and expertise in high-requirement production, such as aseptic conditions,” he explains. “ATMPs, on the other hand, are often at clinical stage and in the hands of researchers without the same experience in building and running production facilities.”

As these products move from the clinical stage to commercial, the owners face new challenges, but Lindholm says that KeyPlants, as a company that has built pharmaceutical manufacturing plants all over the world, has a thorough understanding of the technical and regulatory requirements, so the facilities will be set up for safe delivery of medicines to patients.

“With X-press PODs, pharma companies can be confident that they will receive a facility that meets their project timelines, without compromising on quality.”

No limitation on scale

As a facility that can be up-sized by adding PODs, X-press PODs has no obvious limitations on its scale-up or scale-out capacity, opening up opportunities for future expansion. At the same time, X-press PODs are also a solution for small-scale production of cell and gene therapies, for example.

“A large, conventional plant would not be cost-effective, given the small number of patients for some of these products,” Lindholm points out. “But X-press PODs make it easy to right-size a facility.”

The portable nature of X-press PODs also means they have the capacity to move from one location to another when required. “This ensures PODs can adapt to evolving needs, which is crucial when keeping up with the fast-moving biomanufacturing landscape,” he adds.

About KeyPlants

KeyPlants, headquartered in Stockholm, Sweden, is a leader in the clean room manufacturing space for the life science industry, having executed 100+ projects globally. Our customers benefit from KeyPlants’ vast experience and expertise, resulting in 30-50% shorter timelines and increased predictability with regards to schedule, cost, and quality. KeyPlants deliver PODs and turnkey facilities including process equipment, utilities, and digital solutions. KeyPlants is part of Masco Group.

www.KeyPlants.com

www.KeyPlants.com/x-presspods/

About Masco Group

Masco Group is an integrated solutions provider, partner to top-tier pharmaceutical and biotechnological companies. Its companies Stilmas, Olsa, BCD, DOC, and KeyPlants, are leaders in clean utilities, process technologies, services and facilities. Headquartered in Milan, Italy, the Masco Group has production sites and subsidiaries in Europe, The U.S., and Asia, serving more than 6,000 clients globally and delivering around 300 projects per year.

For further information, please visit our website or contact:

Marija Mladenovic,

Marketing & Communications

marija.mladenovic@keyplants.com

|

October 27-28 2021

Join us at Supply Side West, with Hecht and Lödige (Booth 3922) Mandalay Bay Convention Center, Las Vegas, NV We will be demonstrating Hecht's ProClean Conveyor, the ideal vacuum conveyor for GMP applications, and a Lödige Ploughshare Mixer. Click here for a discounted registration |

|

April 12-13 2022

Join us at Supply Side East, with Hecht and Lödige (Booth 606) Meadowlands Exposition Center - Secaucus, NJ We will be demonstrating powder handling systems, including Hecht's ProClean Conveyor, the ideal vacuum conveyor for GMP applications, and the Lödige Ploughshare Mixer - the ideal mixer for complex supplement blends. |

October 12 2021

KeyPlants Acquires Workshop for Manufacturing of Modular Facilities

KeyPlants to extend leadership in offsite construction for the life science industry with the acquisition of the assets in Swedish Modules, our modular workshop partner with more than 45 years of experience delivering more than 3,500 modules to over 30 countries. Se also:

https://keyplants.com/keyplants-acquires-swedish-modules/

https://youtu.be/WUMHm-HVVQU

KeyPlants Acquires Workshop for Manufacturing of Modular Facilities

KeyPlants to extend leadership in offsite construction for the life science industry with the acquisition of the assets in Swedish Modules, our modular workshop partner with more than 45 years of experience delivering more than 3,500 modules to over 30 countries. Se also:

https://keyplants.com/keyplants-acquires-swedish-modules/

https://youtu.be/WUMHm-HVVQU

May 17 2021

Lödige Process Technology at Achema Pulse

Visit Lödige Process Technology at Achema Pulse, they will take part with 3 live events:

15.06.2021 11:45 a.m. – 12:00 a.m. Process technology for cocoa manufacturing

16.06.2021 8:00 a.m. – 8:30 a.m. Lödige – Your solution provider for the process technology

16.06.2021 11:45 a.m. – 12:00 a.m. Washing in Place (WIP) in horizontal mixing systems

Get your free ticket for Achema Pulse at

https://tickets.achema.de/DECHEMA/ACHEMAPulse2021/Register/Z2p47

Lödige Process Technology at Achema Pulse

Visit Lödige Process Technology at Achema Pulse, they will take part with 3 live events:

15.06.2021 11:45 a.m. – 12:00 a.m. Process technology for cocoa manufacturing

16.06.2021 8:00 a.m. – 8:30 a.m. Lödige – Your solution provider for the process technology

16.06.2021 11:45 a.m. – 12:00 a.m. Washing in Place (WIP) in horizontal mixing systems

Get your free ticket for Achema Pulse at

https://tickets.achema.de/DECHEMA/ACHEMAPulse2021/Register/Z2p47

December 22 2020

KeyPlants releases video illustrating execution of an ongoing project:

keyplants.com/execution-of-modular-facility-projects/

abou

KeyPlants releases video illustrating execution of an ongoing project:

keyplants.com/execution-of-modular-facility-projects/

abou

May 26 2020

ModWave and Partners Covid-19 Update

ModWave and our Partners are closely monitoring the COVID-19 situation as it continues to evolve. The health and safety of our people and our ability to support to our clients is our top priority.

Operations at our Partners’ sites are working well, and projects are executed according to plan. Please reach out if we can support you in any way.

ModWave and Partners Covid-19 Update

ModWave and our Partners are closely monitoring the COVID-19 situation as it continues to evolve. The health and safety of our people and our ability to support to our clients is our top priority.

Operations at our Partners’ sites are working well, and projects are executed according to plan. Please reach out if we can support you in any way.

|

October 17-18 2019

Join us at Supply Side West, with Hecht and Lödige (Booth 3922) Mandalay Bay Convention Center, Las Vegas, NV We will be demonstrating Hecht's ProClean Conveyor, the ideal vacuum conveyor for GMP applications. Click here for a discounted registration |

October 01-02 2019

Join us for the joint Lödige and Alexanderwerk

GRANULATION SEMINAR 2019

at Alexanderwerk Inc in Montgomery, PA

For more information and to register, please see: www.alexanderwerkinc.com/2019/04/17/granulation_seminar_2019/

Join us for the joint Lödige and Alexanderwerk

GRANULATION SEMINAR 2019

at Alexanderwerk Inc in Montgomery, PA

For more information and to register, please see: www.alexanderwerkinc.com/2019/04/17/granulation_seminar_2019/

April 30-May 2 2019

Join us at CpHI, with Hecht and Lödige (Booth 2118)

McCormick Place, Chicago, IL

Use Promo Code: INVITE19HECHT for your free exhibit pass or 20% off conference passes

Join us at CpHI, with Hecht and Lödige (Booth 2118)

McCormick Place, Chicago, IL

Use Promo Code: INVITE19HECHT for your free exhibit pass or 20% off conference passes

March 26-28 2019

Join us at ProFood Tech, with Hecht and Lödige (Booth 775)

McCormick Place, Chicago, IL

Register for free with Code 18V75, or simply using this link:

https://www.xpressreg.net/register/PROF0319/start.asp?sc=18V75

Join us at ProFood Tech, with Hecht and Lödige (Booth 775)

McCormick Place, Chicago, IL

Register for free with Code 18V75, or simply using this link:

https://www.xpressreg.net/register/PROF0319/start.asp?sc=18V75